The purpose of this step is to ensure that you are absolutely clear about the nature and extent of your HACCP study. It involves:

- selecting an appropriate plan

- briefly describing the product

- identifying the start point and end of the study

- considering the likely hazards to be encountered

1. Type of HACCP plan

You are asked to choose between a “Linear” or a “Modular” plan and you should select the appropriate one based on the complexity of your food operation.

A linear HACCP plan is one which considers each product as a whole, starting from the raw materials and ending with the finished product. A modular plan produces a plan made up of a series of building blocks or modules.

Linear plan

This would be suitable for a basic food production process where only a limited number of products are produced. For example, a manufacturer of orange juice may choose this approach because the manufacturing process involves a relatively small number of process steps. However, if the manufacturer decides to extend its product range to include apple, grapefruit and pineapple juices then a modular approach may be more suitable.

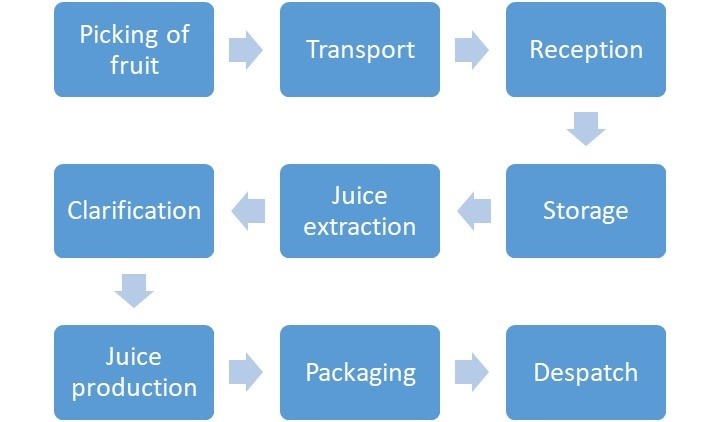

This is an example of a 'linear HACCP' plan because the process flows in a simple line from one process step to another.

The diagram shows a linear plan with stages which follow each other in order.

- Picking of fruit

- Transport

- Reception

- Storage

- Juice extraction

- Clarification

- Juice production

- Packaging

- Despatch

Modular plan

This is the more common approach where the food production process is more complex and typically involves several steps which are shared with other products. The HACCP principles can be applied to specific activities or 'modules' which are then added together to make a complete HACCP plan.

For example, a juice manufacturer may identify the following modules which are common to several products:

- Module 1: Fruit reception

- Module 5: Juice extraction

The hazards and controls will be the same for these operations, irrespective of the type of juice produced and so once the HACCP has been completed for each, they can be used wherever relevant for different products.

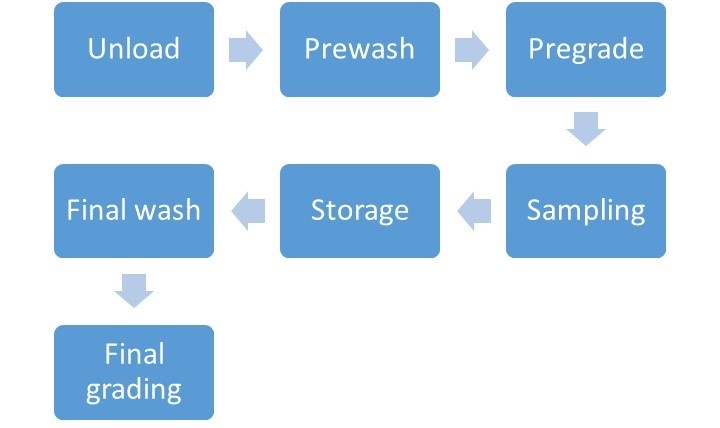

The diagram shows one module of a modular HACCP plan, relating to fruit reception in the production of fruit juices. The module contains steps which follow each other in order. The HACCP plan for each step could be used for any product type where the processes involved are the same, because the hazards and controls will also be the same.

Module: Fruit reception

- Unload

- Prewash

- Pregrade

- Sampling

- Storage

- Final wash

- Final grading

2. Type of product and how it is packed

You may choose to undertake a HACCP study of an individual product or prefer to group similar products together and include them in the same study. Whichever you prefer, you should clearly state your choice and include details of any relevant packaging. For example, “Manufacture of vacuum packed sliced ham” or “Preparation of individually boxed fresh cream cakes”.

3. Start and end points of study

The typical study will begin with the intake of ingredients and will end with the despatch of the final product.

However, in order to achieve food safety, you may need to consider activities not just within your own establishment but also those carried out by others such as distributors, retailers and customers. Of course you cannot be sure how your food is handled once it has left your control, but you should consider whether the study needs to include details of the likely way that others will handle your products and take these into account by, for example, providing instructions on the product label and/or packaging for storage and use.

4. What hazards will the HACCP plan cover?

The purpose of this step is to identify a “long list” of potential hazards which may be relevant to the production of your food. Hazards are anything which have the potential to cause harm and you will be required to identify hazards which fall into four categories: Physical, Chemical, Microbiological and Allergens.

- Physical hazards are specifically associated with a food, for example bones in fish or stones in fruit, or where a residual risk exists once appropriate pre-requisite controls have been put in place. For example, glass contamination in areas where products are packed in glass containers.

- Chemical hazards might include, for example, detergent residues from cleaning or chemical residues from farming practices such as antibiotic residues in milk.

- Microbiological hazards will include relevant bacteria, such as Salmonella, viruses such as norovirus and parasites such as nematodes. In most cases microbiological hazards should be specifically identified rather than merely classifying them by type such as “bacteria” or “viruses”. This is because different microorganisms will have different growth, death and survival characteristics which must be addressed separately in the HACCP plan.

- Food allergens: There are many foods which may cause allergies or intolerances to susceptible consumers but for the purposes of HACCP only the 14 allergens listed in Annex II of Regulation (EU) 1169/2011 need to be considered. These are:

- Named cereals containing gluten

- Crustaceans

- Sesame seeds

- Sulphur dioxide & sulphites

- Fish

- Soybeans

- Mustard

- Peanuts

- Celery

- Eggs

- Milk

- Named nuts

- Molluscs

- Lupins

At this stage, you are simply choosing hazards from a suggested list which you consider might be relevant to your food. You will be required to evaluate these hazards, identifying those which are significant and placing them on a 'short list' later in the study.

Feel free to add any other hazards that you can think of but which are not included in the list, but do not get carried away. You should take a realistic approach to this step and only include hazards that are likely to be of concern.

5. Details of any documents used in the HACCP plan

There are a number of documents that are relevant to your HACCP study but in this part of the tool you should record those documents which either set out your procedures for implementing an effective pre-requisite programme (explained in Preparatory Stage A) or those documents that you have relied upon to identify hazards.

For example, you may wish to make reference to your prerequisite documentation and relevant legislation/guidance which might include: